Shadow foam is a versatile material, that allows us to create bespoke foams for tool kits and much more.

The tool kits that we sell, all come with shadow foam included in the price. The purpose of the foam is to act as a tool solution, it keeps tools organised and helps to make it easier to spot when a tool is missing. Many man hours are lost to searching for missing tools, so shadow foam inserts help to maintain high productivity levels.

We can create bespoke foams based around brand new tools that you buy from us, or we can create bespoke foams on your own existing tools.

The Process

Firstly, we scan each tool. Tools are set down on an electronic board using Plasticine, this keeps the tools in place. We then use an electronic pen to draw around each individual tool. This creates a design on the PC.

With these electronic copies of the outlines of the tools, we can use software to create designs. Each tool is placed so that it perfectly fits into each layer. Tools will split into categories, so if your tool includes a variety of pliers, we will create a “plier layer”.

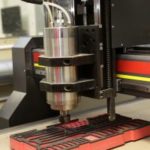

Once the design has been approved by the customer. Tool paths are created. Tool paths are codes from the computer that transfer to the CNC Router. A Router is what is used to cut the foams with the shapes from the design.

Once this is done, the foams are cleaned and tools are placed inside. Then they are ready to fit into your tool kit!

We can create shadow foaming® solutions for much more than just tools kits. A recent project we worked on, was to create foams for a manicure set. The possibilities are endless for foams that we can create around the home and garage, as well as the workplace.

For more information on bespoke shadow foaming® click here.